An example of Purchasing 4.0 could look like this: In a digitized world, buyers receive real-time data on their tablets at the push of a button. This way, he can quickly decide if, for example, suppliers have to be delisted due to a crisis. In parallel, orders and order confirmations run automatically in the background. That means less time for administrative work and more space for productive work. However, this scenario still sounds like a dream of the future, particularly in mechanical and plant engineering.

The main problem: First of all, there are different opinions as to what exactly is Industry 4.0 and Purchasing 4.0, i.e. the digitalization of business processes, according to the expert and consultant Friedrich Klement from Phoron Consulting: “For some, processing orders by e-mail -Mail is already digitization. For the others, the next big step would be to strengthen strategic purchasing internally and externally due to its role and networking within the company. ”The automotive industry is considered a pioneer here. Because here the operational and administrative purchasing processes - from the inquiry to the order confirmation to the invoice process - are largely automated via electronic procurement process (EDI) and e-procurement tools. But best practices from the automotive sector cannot be adapted arbitrarily. One of the reasons for this is that machine and system builders cannot exchange standard materials or articles with their suppliers for each individually designed part.

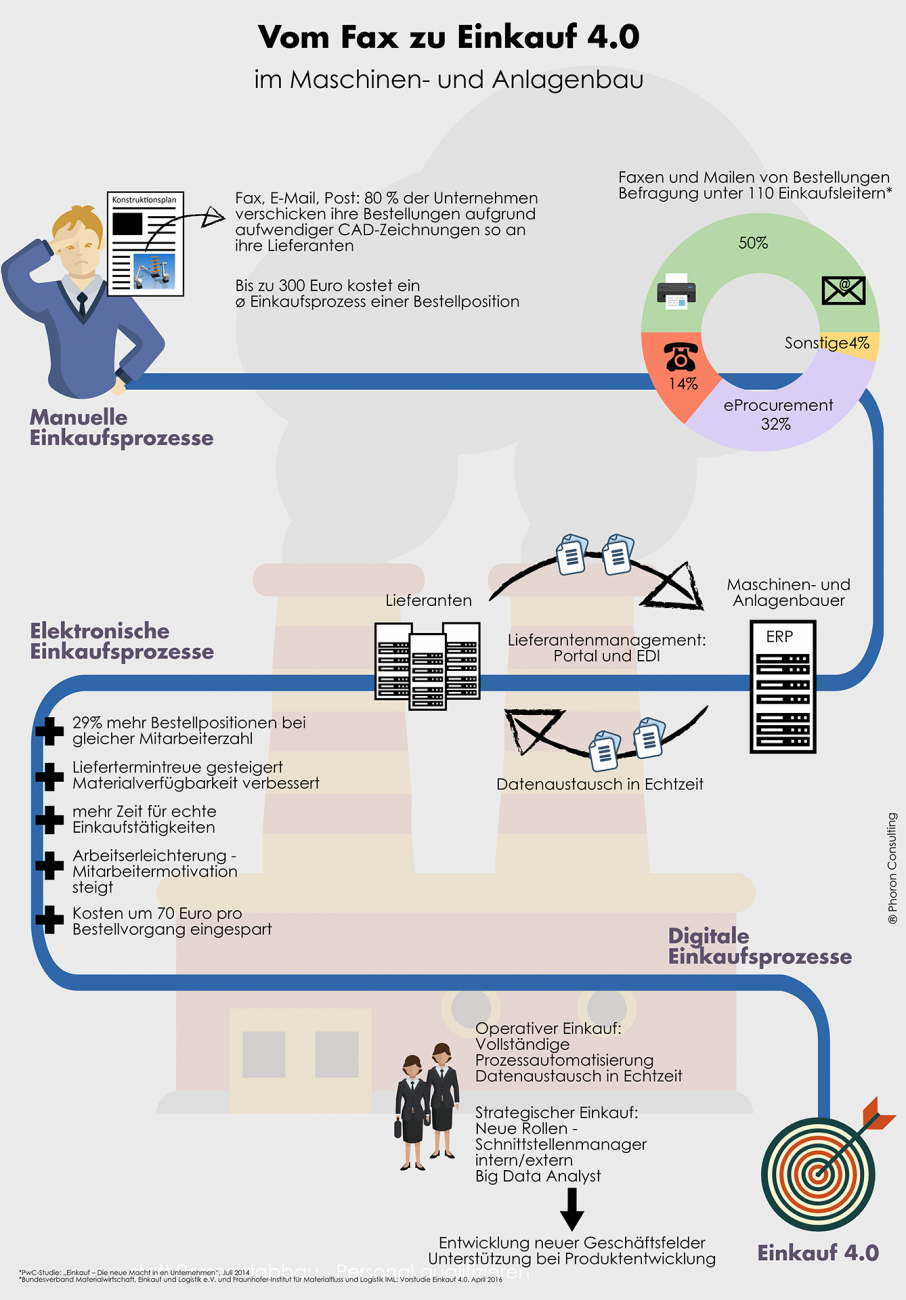

According to a BME study, there is agreement among the CPOs in changing the tasks in purchasing. However, Klement does not believe that operational and administrative purchasing will completely disappear: “Operational purchasing is, for example, negotiating contracts, and that still requires a great deal of purchasing know-how. At the same time, an incredible amount of time is invested in senseless processes that cost money. If we look at the procurement processes of a machine or plant manufacturer, then the costs make up 40 percent of the overall process. That's a lot of money that can be saved with the right tools. ”But the purchasing process at 80 percent of German-speaking companies is still conventional: For example, the purchaser still has to obtain the design drawing for ordering the necessary parts and save them on a medium and send to the supplier by fax or email. This is also shown by a recent study, according to which more than three fifths of those surveyed still use faxes or emails in their companies to prepare and send tenders.

Purchasing processes in real time are also the goal of pester pac automation GmbH, a machine and plant manufacturer for packaging machines from Wolfertschwenden im Allgäu. In the first step of digitization, global procurement processes should be faster and the costs per order process reduced. That is why the Beyond.Procurement tool was chosen: "We introduced the supplier portal from the Phoron solution package for purchasing," said Klement. “This means that the suppliers of the machine and plant manufacturer are connected via the portal, link and EDI. Data can now be exchanged and processed in real time via these three channels. This means that 100,000 order items are currently being processed electronically in 2016. That is 30 percent more order items within a year. ”Today, 93 percent of the order processes that used to take place via email communication with the supplier are automated. Overall, the costs for an order process could be reduced to 20 euros. That is an average of 70 euros less than comparable companies.

The goal must therefore be that systems communicate with each other independently or semi-automatically and that there are no longer any media breaks. This often fails due to the outdated IT infrastructure, which can no longer properly process and provide large amounts of data. In fact, according to the preliminary study Purchasing 4.0, many companies are critical of the introduction of new systems. Above all, suitability, ability and compatibility are questioned.

Therefore, a lot of persuasion is necessary to implement the digital change in the company. The involvement of employees is one of the most important from the start. Klement: “It doesn't help if you explain to the customer that, for example, our shopping tool will pay for itself in six months. It is important for buyers to know to what extent their tasks change. Therefore, change management makes up the majority of such projects. Because with the introduction of a procurement suite, the quality of the work changes and the employees gain more time for more meaningful, more strategic activities. “So it is not a question of reducing personnel in purchasing with the new digital tools, but of upgrading their tasks towards “real shopping”.