According to a survey by BME and the Oliver Wyman strategy consultancy, half of the European purchasing managers surveyed are also convinced of this. However, purchasing is still at the very beginning. The biggest challenge when implementing big data in purchasing is the "what and how".

“Very few companies have a precise idea of what should be analyzed and evaluated from the amount of data. Many people in charge also find it difficult to draw the right conclusions for a decision-making basis in purchasing. ” Martin Zauner, procurement expert at Phoron Consulting

Big data analysis can also save a lot of money, such as reducing the opportunity costs when evaluating suppliers. With the help of company data, suppliers can be clustered or used to consolidate suppliers. This reduces the supplier base and thereby reduces opportunity costs. Additional data from external data sources, such as raw material indices, statistical data, price level facts or supplier discussions in the network, can also help to summarize the information relevant for decision-making. Operational purchasing also has a lot of potential for saving costs by examining the entire procurement process for throughput times, deviations from the target or unnecessary cost drivers. The “how”, that is to say the concrete implementation, represents the smallest hurdle here, since IT systems today provide everything for such big data analyzes in purchasing.

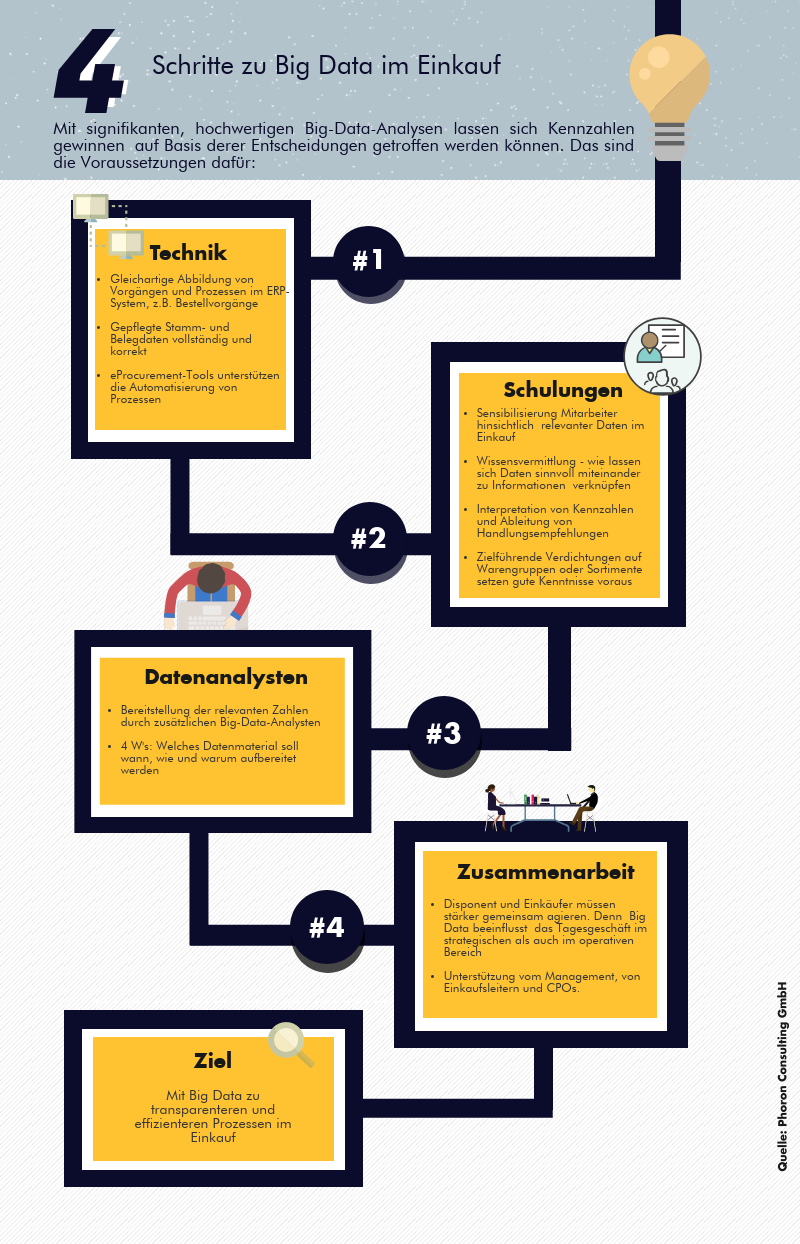

This graphic shows which requirements have to be met in order to use Big Data in purchasing: